Inches matter, installing an incorrectly measured hose can result in extra expenses or time delays. Many hose installers aren’t trained on how to correctly identify and measure hose lengths.

There are two ways hose length can be identified, overall length or cut length. Overall length (OAL) is typically the most common way the length of a hose is specified.

Overall Length

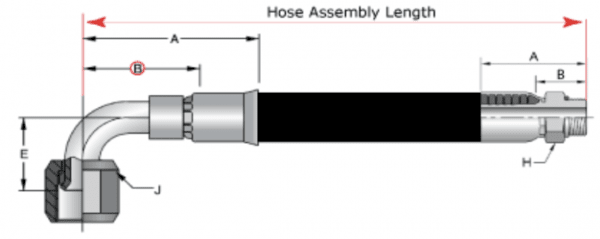

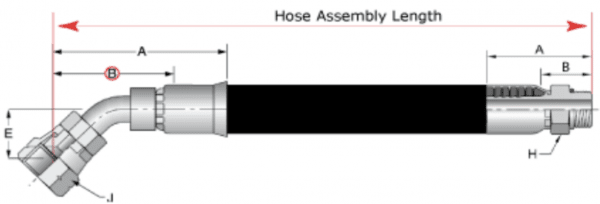

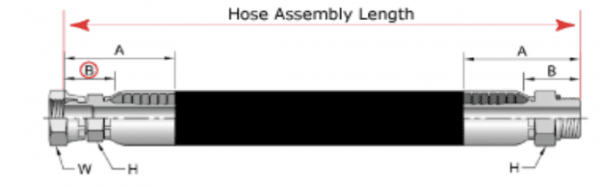

Knowing how to measure the overall length of a hose is extremely important when assembling a hydraulic application. There are three things you must keep in mind when measuring a hose’s overall length:

- Male ends are measured from the end of the threads

- Female ends and flanged ends are measured from their sealing surface

- Angled ends are measured from the center of their sealing surface

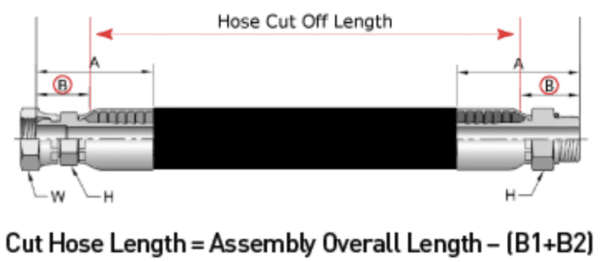

Cut Length

Cut length has everything to do with specs. In order to find the cut length of a hose, you have to subtract the cut-off factor (distance from the bottom of the collar to the end of the fitting) from the overall length.

Important Factors

Whether you are using overall length or cut-off length there are some factors you should be conscious of:

- Hose length will contract or expand under pressure (usually 2 – 4%)

- Allow for extra length so that fittings don’t undergo pull-off forces

- Cut the new hose the same length as the one being replaced

- Don’t clamp high and low-pressure hoses together

- Don’t clamp hoses at their bends

- Avoid stretching the hose

Click here to read more about our feature in Feedspot’s Top-10 Wind Power Industry Podcasts!

Categorised in: Latest Wind Power Industry News - Kurz Wind Division

This post was written by Aaron Rood

Comments are closed here.